Have any questions?

+44 1234 567 890

The VetterTec Ring and Flash Dryer technologies are pneumatic type drying systems well-known for their reliability and drying efficiency. Our Ring and Flash Dryer systems are suitable for drying a range of products from wet cakes to wet pastes.

Optimal wet product preparation is part of our specially designed and easily cleanable wet product feed system forming an integral part of our dryers. Based on our extensive experience, VetterTec carefully selects each part of our drying systems, including, for example, upstream mechanical dewatering and downstream Milling and Cooling to suit each specific application.

As a leading supplier, VetterTec builds on its proven, innovative solutions to ensure that all our drying systems meet our customers’ changing needs while continuously delivering optimal product quality.

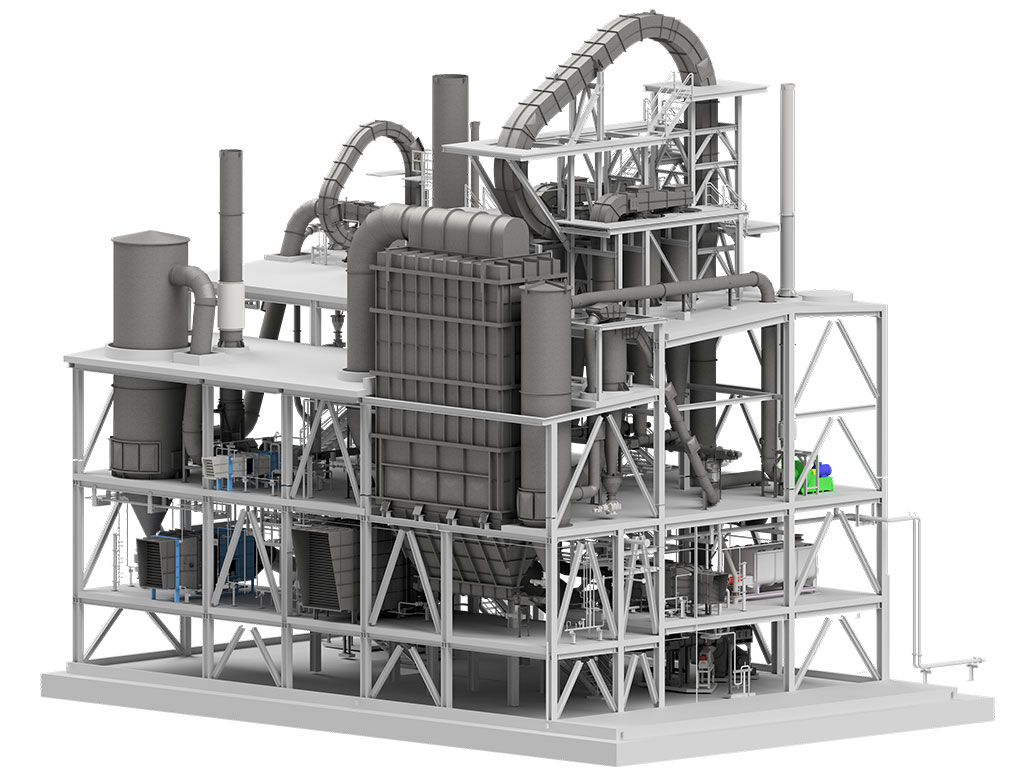

The Flash Dryer – Principle of Operation

The Flash dryer is a single-pass, pneumatic type drying system which offers gentle drying due to its short residence time. The dryer can be either indirectly heated (steam, thermal oil, waste heat or natural / biogas) or directly heated (waste heat or natural / biogas). Depending on product and / or emission requirements, either single or multi-stage cyclones (with option for special suction discharge), cyclone and bag filter combination or bag filter only can be used for product collection.

Dryer Stack

Main Bag Filter 2

Milling/Cooling Line Air Intake

Main Bag Filter 1

Dryer Air Intake

Flash Dryer 2

Flash Dryer 1

Dryer Stack

Dryer Feed System

Multi Cyclone

Corn Starch and Wheat Starch Flash Dryer

Advantages

Direct or indirect heated dryer

Suitable for wet cakes and pastes

Gentle drying due to short residence time

Low maintenance cost – only a few moving parts

Suitable for drying in an inert atmosphere

Option for exhaust gas recycle to provide inert atmosphere for increased safety and save heating energy

Design in accordance with all relevant ATEX/NFPA or similar local requirements

Design is optimized for easy cleanability of wet process

The Flash Dryer – Fields of Application

Flash Dryers are used for various products, preferably for fine product when gentle drying is required.

VetterTec Flash Dryers are employed for a wide range of applications by adjusting the wet feed system, dryer inlet/outlet temperatures and product collection system.

According to requirements, it may be required to run drying tests with the product at our pilot plant facilities in Germany and Canada.

Starch Industry

Food Industry

Chemical Industry

Pulp & Paper and Environmental Industry

Your application is not on the list? Feel free to contact us:

we have several test facilities, combined with our long-term experience in the drying we would be pleased to consult for the best drying solution for your product.

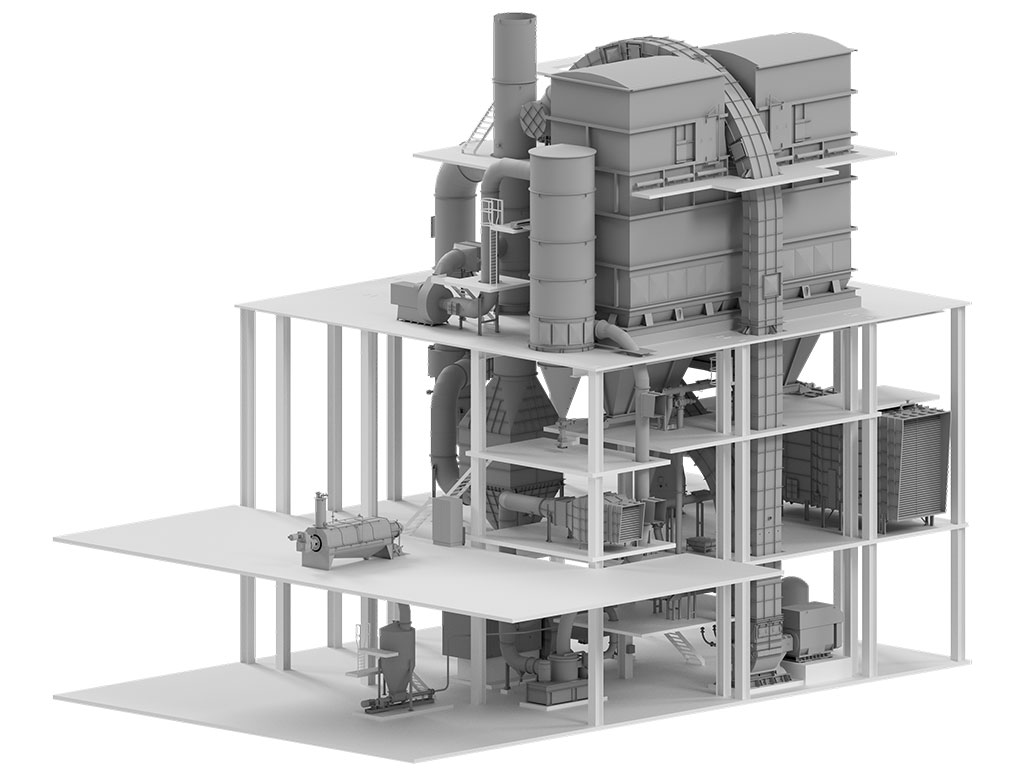

The Full Ring Dryer – Principle of Operation

The Full Ring Dryer is a multi-pass, pneumatic type drying system with a multi or single stage classifier for selectable particle residence time which offers gentle drying due to its overall short residence time. The dryer can be either indirectly heated (steam, thermal oil, waste heat or natural / biogas) or directly heated (waste heat or natural / biogas). Depending on product and / or emission requirements either single or multi-stage cyclones (with option for special suction discharge), cyclone and bag filter combination or bag filter only can be used for product collection.

Dryer Stack

Milling/Cooling Line Bag Filter

Milling/Cooling Line Air Intake

Mechanical Dewatering System

Milling System

Hot Disintegrator

Dryer Air Intake

Full Ring Dryer

Main Bag Filter

Vital Wheat Gluten Full Ring Dryer including Mechanical Dewatering (VetterTec Screw Press) and Milling / Cooling System

Advantages

Direct or indirect heated dryer

Suitable for wet cakes and pastes

Multi or single stage classifier for selectable particle residence time

Choice of various disintegrators and dispersers

Wet feed introduced at reduced inlet temperature

Semi-dry product recirculates to hottest air

Gentle drying due to short residence time

Low maintenance cost – only a few moving parts

Suitable for drying in an inert atmosphere

Option for exhaust gas recycle to provide inert atmosphere for increased safety and save heating energy

Design in accordance with all relevant ATEX/NFPA or similar local requirements

Design is optimized for easy cleanability of wet process

The Full Ring Dryer – Fields of Application

Full Ring Dryers are used for various products, preferably when extended residence time (compared to flash dryers) is required to meet the final product moisture requirement.

VetterTec Full Ring Dryers are employed for a wide range of applications by adjusting the wet feed system, dryer inlet/outlet temperatures, internal and external product recycle and product collection system.

According to requirements, it may be required to run drying tests with the product with our pilot plant facilities in Germany and Canada.

Starch Industry

Food Industry

Chemical Industry

Pulp & Paper and Environmental Industry

Your application is not on the list? Feel free to contact us:

we have several test facilities, combined with our long-term experience in the drying we would be pleased to consult for the best drying solution for your product.

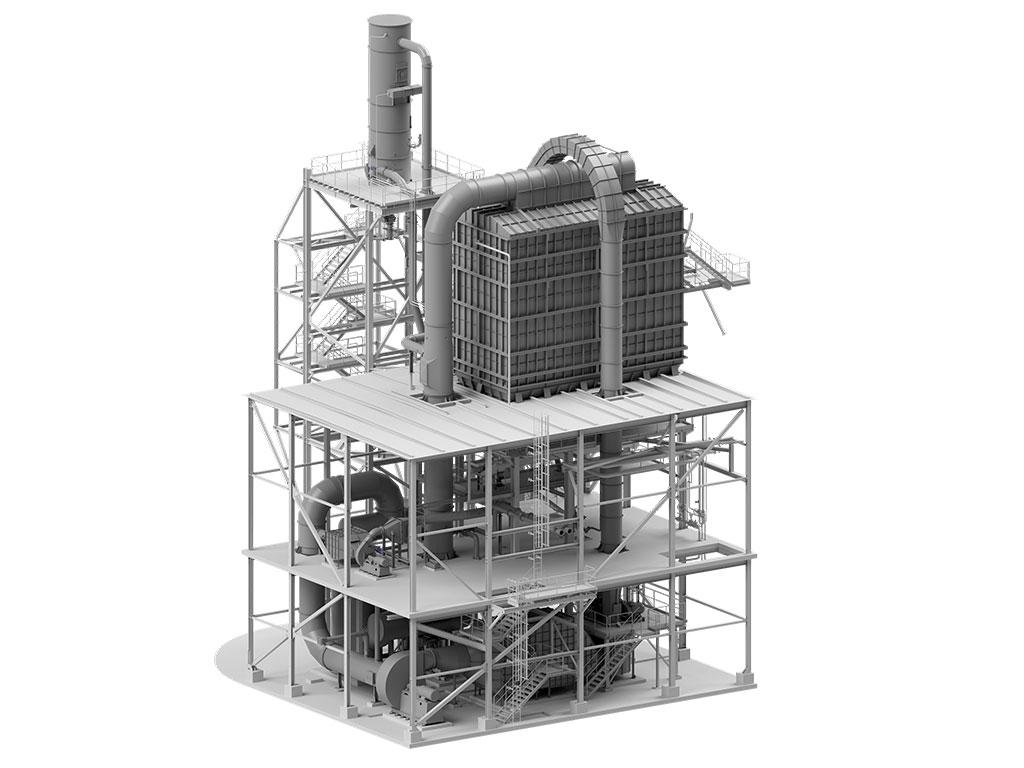

The Feed-Type Ring Dryer – Principle of Operation

The Feed-Type Ring Dryer is a multi-pass, pneumatic type drying system with a single stage classifier for selectable particle residence time which offers gentle drying due to its overall short residence time. The dryer can be either indirectly heated (steam, thermal oil, waste heat or natural / biogas) or directly heated (waste heat or natural / biogas). Depending on product and / or emission requirements either single or multi-stage cyclones (with option for special suction discharge, cyclone and bag filter combination or bag filter only can be used for product collection.

Cooling Line Bag Filter

Main Fan

Air Heater

Dryer Feed System

Inertising Gas Inlet

Main Bag Filter

Feed Type Ring Dryer

Feed-Type Ring Dryer for Lignin

Advantages

Direct or indirect heated dryer

Suitable for wet cakes and pastes

Cold disintegrator with single stage manifold

Can incorporate a pre-separator to collect the bulk of the material before the cyclones

Large evaporative capacities

Can be designed for operation in an inert atmosphere with exhaust gas recycle

Gentle drying due to short residence time

Low maintenance cost – only a few moving parts

Suitable for drying in an inert atmosphere

Option for exhaust gas recycle to provide inert atmosphere for increased safety and save heating energy

Design in accordance with all relevant ATEX/NFPA or similar local requirements

Design is optimized for easy cleanability of wet process

The Feed-Type Ring Dryers – Fields of Application

Feed-Type Ring Dryer are used for various products, preferably when extended residence time is required to meet the final product moisture requirement.

VetterTec Feed-Type Ring Dryer are employed for a wide range of applications by adjusting the wet feed system, dryer inlet temperature, internal and external product recycle and product collection system.

According to requirements, it may be required to run drying tests with the product with our pilot plant facilities in Germany and Canada.

Starch Industry

Food Industry

Chemical Industry

Pulp & Paper and Environmental Industry

Your application is not on the list? Feel free to contact us:

we have several test facilities, combined with our long-term experience in the drying we would be pleased to consult for the best drying solution for your product.

VetterTec Flash and Ring Drying System – Design Examples

VetterTec Ring and

Flash Dryers

VetterTec Ring and Flash Dryers

(in Portuguese)

VetterTec Ring and Flash Dryers

(in Spanish)