Have any questions?

+44 1234 567 890

Let’s dry it!

For all of its technologies, VetterTec has testing units which are used for continuous technology and application developments as well as for product developments by our customers.

Services:

Feasibility studies

Evaluation of process parameters

Sample production

Determining of upscale parameters

Process optimization

Tests on site and in our test centres

Our values:

Professional and experienced staff

Lab equipment for analysis available

Integrity

Scale up

Friendly people

You are not sure, if or how your product could be dried?

Feel free to contact us: We have several test facilities – also for food-grade products, which meet highest hygienic standards. Combined with our experienced process engineers we would be pleased to consult for the best drying result of your product.

Test Centre and Equipment

Spray Drying Test and Research Centre

Our fully equipped research and development spray drying facility offers the opportunity to test in different configurations. With internal fluid bed, external fluid bed, rotary atomizers, high pressure nozzles, twin-fluid nozzles and homogenizer, the spray dryer can be adapted to customers’ needs. Evaporation capacity depending on temperature ranges between 2 and 20 l/h. Testing can be carried on food and dairy products as the facility meets all hygienic processing standards (FDA standard).

- Multifunctional

- Self-developed bivalent air distributer

- Internal and external fluid bed

- High pressure pump / homogenizer

- Clean room conditions with personnel air lock

- Rotary and nozzle atomization

- CIP unit

- Indirect heated

- Mobile units

- Lab equipment available

Ring and Flash Test Dryers

- Multifunctional

- Transportable

- Drying temperatures adjustable up to 400°C

- Flash dryer configuration

- Feed type configuration

- Ring dryer configuration

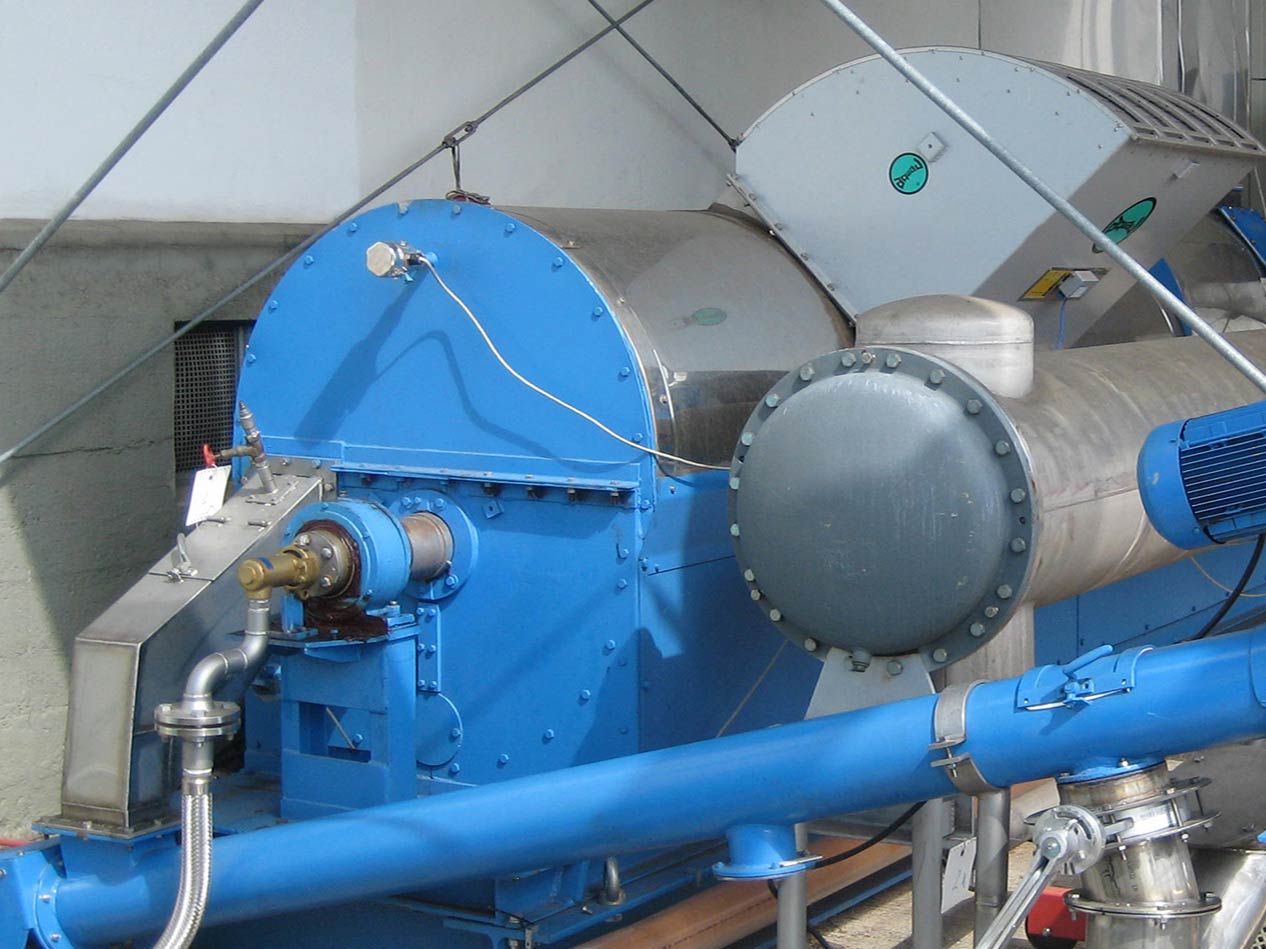

Tube Bundle Test Dryers

- Multifunctional

- Two test plants

- Transportable version available

- Mixing and recycling system

- Gas-tight design available

- Recycling system

- Steam boiler

- Pre-milling

- Pre-heating of products

- Evaporation from 10 kg/h to 150 kg/h

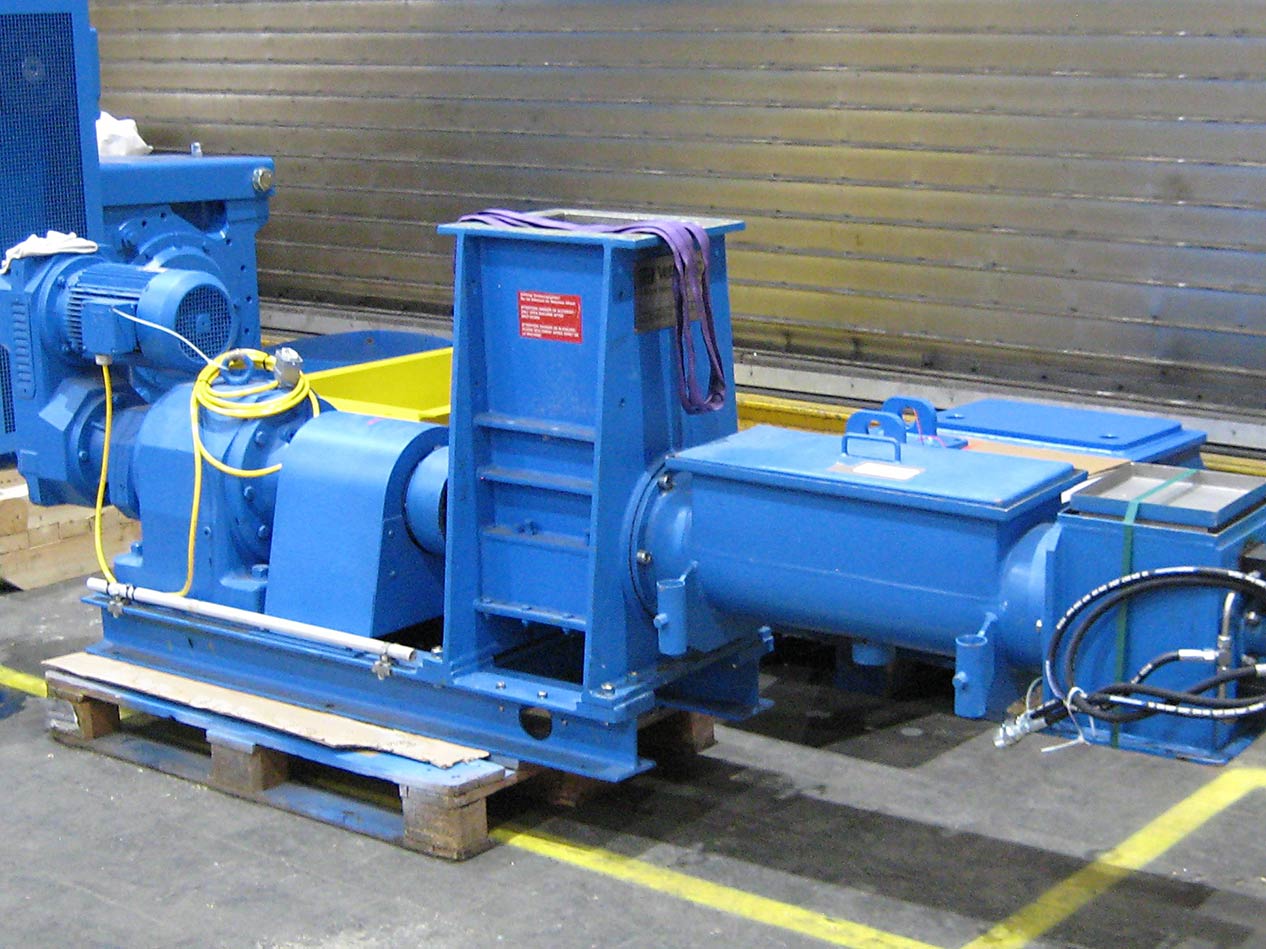

Test Screw Presses

- Wide range of presses available

- Different setups with screens, baskets and screws

- Pre-treatment with mixers and cutters possible

- Twin screw press available

- Capacities from 5 kg to 5.000 kg wet feed

- Retention cone

- Control cabinet

- Many other features available